- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Email: sales@njrecgroup.com

Views: 0 Author: Site Editor Publish Time: 2025-07-17 Origin: Site

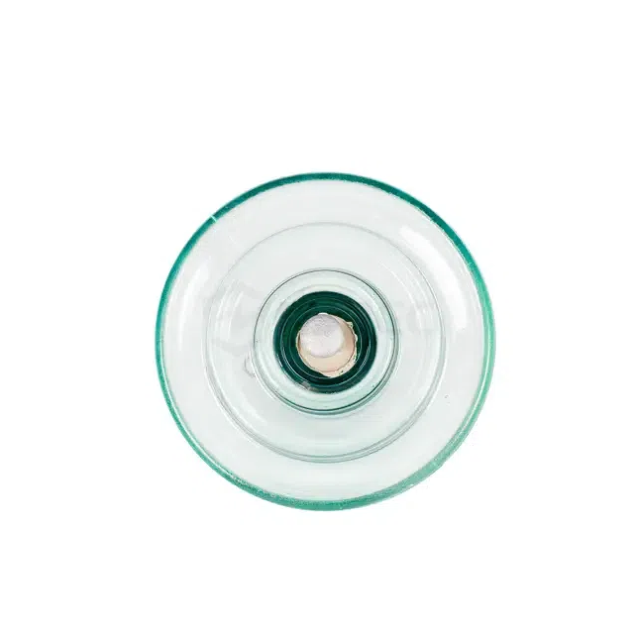

In high-voltage power transmission systems, reliability is everything. The consistent delivery of electricity across vast distances depends on durable, well-designed components that can endure environmental and mechanical stress. Among these, the anti-pollution glass insulator plays a crucial role in minimizing flashover risks, especially in challenging environments. By integrating aerodynamic principles and specialized shed designs, these insulators significantly enhance the stability and safety of power networks.

At Nanjing Rainbow Electric Co., Ltd. (NJREC), we provide innovative solutions tailored to real-world grid challenges. Our product range includes advanced models like the U120BP, U210BP, UG70BSA, and U120BLA—glass insulators engineered to resist heavy pollution, withstand harsh weather, and improve electrical performance. Whether your infrastructure is located in coastal regions, industrial zones, or desert environments, NJREC’s glass insulators are built for reliability and long-term efficiency.

Anti-pollution and aerodynamic glass insulators are specially designed high-voltage insulators that address the common problem of contamination-related flashovers. Over time, pollutants such as salt, dust, or industrial chemicals can accumulate on the surface of insulators, especially in environments with high humidity or air pollution. When wet, these contaminants create a conductive path, leading to dangerous electrical discharge—known as pollution flashover.

NJREC’s U120BP and U210BP are anti-pollution glass insulators that feature extended creepage distances and improved shed geometries. These designs prevent the formation of continuous conductive films, minimizing the risk of leakage current and flashover. Similarly, our UG70BSA and U120BLA models incorporate aerodynamic features that help reduce pollution accumulation by encouraging self-cleaning through natural airflow.

Both types are made from toughened glass, ensuring high mechanical strength, excellent dielectric performance, and durability under extreme environmental conditions. Their smart geometry combined with material integrity makes them the preferred choice for critical infrastructure.

Flashovers due to pollution are a leading cause of failure in high-voltage systems. These events can result in power outages, equipment damage, and safety risks. The design of anti-pollution glass insulators directly addresses these issues by altering the insulator's surface profile and increasing the creepage distance—the shortest path along the surface between two conductive parts.

One of the key innovations is the use of alternating shed profiles, which create complex airflow patterns and prevent pollutants from forming continuous paths across the insulator. Compared to traditional designs, these advanced profiles—used in NJREC’s U120BP and U210BP—effectively break up water films and allow contaminants to be washed off more easily during rain or wind exposure.

According to studies from sources like Nature.com and La Granja Insulators, these shed designs lead to a substantial drop in pollution-induced discharge, especially in high-humidity or coastal environments. Flashover voltage tests have shown that such designs can increase system protection by over 30%, offering a much higher return on investment in the long term.

Aerodynamic glass insulators go a step further by modifying the airflow around the insulator surface. Pollution tends to settle on areas with stagnant air or where turbulence traps dust and moisture. By incorporating streamlined shapes—like those found in NJREC’s UG70BSA and U120BLA models—the airflow remains more uniform, reducing dust accumulation and allowing natural wind or rain to clean the surfaces effectively.

These aerodynamic features are especially useful in areas with consistent wind patterns or seasonal dust storms. Field testing has demonstrated that such designs lead to lower rates of surface contamination, as well as reduced frequency of manual cleaning. Over time, this not only improves performance but also reduces maintenance costs and downtime.

Furthermore, gap optimization in the shed spacing improves insulation coordination. The design avoids sharp corners and abrupt transitions, reducing corona discharge points and improving dielectric uniformity across the entire insulator string.

Anti-pollution and aerodynamic glass insulators are essential in environments where standard insulators would fail prematurely due to surface contamination. These environments include:

Industrial zones with heavy emissions of ash, smoke, or chemicals.

Coastal areas, where salt spray and high humidity are common.

Arid regions, where dust and sand particles can quickly accumulate.

Agricultural zones, where fertilizer sprays and organic residues may impact insulation.

Typically, these insulators are applied in systems with voltage levels ranging from 66 kV to 1000 kV, covering both distribution and transmission applications. Depending on the mechanical load and installation configuration, NJREC’s models can be selected for use in suspension, tension, and post-type applications. Their adaptability across voltage classes makes them suitable for retrofitting older systems as well as designing new ones.

At NJREC, we understand that no two projects are alike. That’s why we offer customization options for our anti-pollution glass insulator product line to meet specific operational and environmental needs.

Double shed designs: Ideal for extending the creepage distance and enhancing performance in ultra-high pollution zones.

RTV (Room Temperature Vulcanizing) silicone coatings: Applied to improve hydrophobicity, reduce wetting, and further delay pollution-induced flashover.

Mechanical ratings: Custom tensile strength options from 70 kN to 550 kN, ensuring compatibility with conductor tension and span requirements.

Color and transparency variations: For special visual or inspection needs, different glass shades can be provided to improve detectability of faults or harmonize with existing infrastructure.

In addition to standard models like U120BP and UG70BSA, we also support fully bespoke designs based on IEC or ANSI requirements. Our engineering team collaborates with clients from the early design phase to final testing, ensuring every NJREC insulator performs exactly as required.

While anti-pollution and aerodynamic glass insulators are designed to minimize maintenance, periodic inspections and proper care can significantly extend their operational life and reliability.

Here are a few best practices:

Visual inspections: Conduct regular checks for signs of surface contamination, mechanical damage, or glass discoloration.

Scheduled cleaning: In heavily polluted zones, mechanical or water-based cleaning may be necessary. Aerodynamic designs reduce this need but do not eliminate it entirely.

Flashover history tracking: Maintain records of any discharge events to assess trends and preempt failures.

Check fittings and hardware: Ensure metal end fittings are secure and free from corrosion, especially in marine or industrial environments.

Use of drones or infrared scanning: Modern utilities employ advanced tools to detect temperature anomalies or structural cracks, improving safety and minimizing manual labor.

With the right maintenance plan, NJREC’s anti-pollution glass insulators can deliver optimal performance for decades, offering long-term security for your power network.

In modern power systems, smart design leads to stronger reliability. NJREC’s anti-pollution glass insulator solutions, including aerodynamic and specialized shed models, are built to perform under the most demanding environmental conditions. From industrial haze to coastal salt, our insulators prevent flashovers, reduce maintenance, and extend the life of transmission infrastructure. As energy networks expand into more diverse terrains, using the right type of insulator becomes essential for safe, stable delivery. Reach out to Nanjing Rainbow Electric Co., Ltd. (NJREC) to explore how our tailored solutions can meet your specific project demands.

For more technical support or to request a quotation for our anti-pollution or aerodynamic glass insulators, contact us today.