- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Email: sales@njrecgroup.com

Views: 0 Author: Site Editor Publish Time: 2025-06-06 Origin: Site

In the realm of electrical power distribution, switchgear systems play a crucial role in controlling, protecting, and isolating electrical equipment to ensure safe and reliable power flow. A fundamental component within these systems is the bushing — a device that provides an insulated pathway for electrical conductors to pass through grounded barriers such as transformer tanks or switchgear enclosures.

With the increasing demand for higher reliability, compactness, and environmental compliance, the insulation requirements for bushings in switchgear systems have become more stringent. Among the various bushing materials, epoxy resin bushings have emerged as a preferred solution, offering exceptional insulation performance coupled with mechanical robustness.

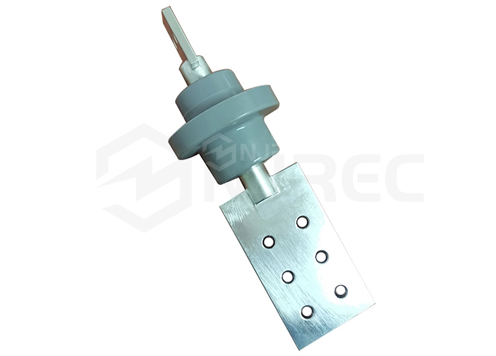

An epoxy resin bushing is an insulating component typically made by molding high-grade epoxy resin mixed with fillers to achieve superior electrical, thermal, and mechanical properties. The resin forms a solid, compact, and homogeneous insulation barrier around the conductor, preventing electrical discharge and ensuring safe current passage.

Unlike conventional porcelain or oil-impregnated paper bushings, epoxy resin bushings are manufactured using modern casting and curing techniques that yield consistent quality and complex shapes tailored to specific applications. The resin matrix is often reinforced with glass fibers or other additives to enhance strength and durability.

Epoxy resin bushings offer multiple advantages compared to traditional porcelain or oil-impregnated paper (OIP) bushings:

Lightweight and Compact: Epoxy resin bushings are significantly lighter than porcelain, allowing easier installation and reducing structural load on equipment.

Superior Mechanical Strength: The resin matrix provides better impact resistance and resilience to vibration or shock.

Enhanced Insulation Properties: Homogeneous structure with minimal internal defects lowers the risk of partial discharge and tracking.

Environmental Safety: Being oil-free eliminates the risk of leaks and contamination, supporting eco-friendly operations.

Cost-Effective Manufacturing: Resin bushings can be molded into complex shapes in fewer production steps, reducing costs and lead times.

These benefits make epoxy resin bushings highly suitable for modern switchgear that demands compact, reliable, and eco-friendly components.

One of the most critical properties for any insulating material used in switchgear bushings is its dielectric strength—the ability to withstand high electric fields without breaking down. Epoxy resin bushings possess a remarkably high dielectric strength, often surpassing 20 kV/mm, which means they can endure strong voltages while maintaining their insulating integrity.

This impressive dielectric performance is attributed to the resin’s homogeneous and void-free microstructure. During manufacturing, advanced molding and curing techniques ensure minimal internal defects, which are typical weak points where electrical breakdowns can originate. As a result, epoxy resin bushings maintain superior resistance to electrical stress, reducing the likelihood of flashovers or short circuits that could compromise the switchgear’s functionality and safety.

In real-world operating environments, switchgear bushings are exposed to various contaminants such as dust, moisture, and chemical pollutants, which can severely affect insulation performance. Tracking is a phenomenon where electrical discharges cause the formation of carbonized conductive paths on insulating surfaces, gradually deteriorating the material.

Epoxy resin bushings inherently resist tracking due to their smooth, non-porous surface finish and excellent hydrophobicity (water-repellent properties). These features prevent the accumulation of contaminants and water films that often facilitate tracking on traditional porcelain bushings.

Additionally, epoxy resin bushings excel in minimizing partial discharge (PD), which are localized dielectric breakdowns within the insulation. PD is a major cause of premature bushing failure as it generates heat and chemically degrades insulating materials. The isotropic and high-purity nature of epoxy resin insulation leads to uniform electric fields inside the bushing, significantly lowering PD risk and thus extending service life.

Switchgear bushings must consistently perform under high-voltage conditions, often exceeding tens or even hundreds of kilovolts. Epoxy resin bushings demonstrate outstanding stability under these demanding voltages.

Their intrinsic high dielectric strength combined with excellent thermal conductivity allows them to dissipate heat generated from electrical losses efficiently. This prevents hot spots and thermal degradation, which are common failure modes in insulation systems. Furthermore, epoxy resin bushings maintain reliable insulation performance over a wide range of operating voltages and transient conditions, such as switching surges and lightning impulses, ensuring safe operation in all scenarios.

Switchgear components routinely encounter thermal stress due to both electrical loading and ambient temperature fluctuations. Over time, this can degrade insulation materials, reducing mechanical strength and dielectric performance.

Epoxy resin bushings are designed to withstand heat aging, meaning they retain their physical and electrical properties after extended exposure to elevated temperatures—often up to 130°C or higher depending on resin grade. The cross-linked polymer structure of epoxy resin provides excellent resistance to thermal breakdown, preventing embrittlement, cracking, or discoloration.

This robust heat aging resistance translates to a longer operational lifespan and reduced maintenance cycles, which is essential for critical infrastructure where reliability is paramount.

Moisture ingress and environmental pollution present significant challenges to insulation in outdoor and industrial switchgear installations. Water can penetrate porous insulation materials, creating paths for electrical discharge and increasing the risk of failure.

Thanks to their low water absorption rate and non-porous surface, epoxy resin bushings offer superior moisture resistance. Their hydrophobic nature causes water to bead and run off rather than accumulate, minimizing wetting and tracking risks.

Additionally, the smooth surface discourages the buildup of pollutants such as dust and industrial contaminants. This makes epoxy resin bushings particularly suitable for use in harsh environments such as coastal areas, chemical plants, and urban installations where airborne pollutants are prevalent.

Modern power distribution systems increasingly rely on compact, modular switchgear designs to optimize space and facilitate easier installation and maintenance. Traditional porcelain bushings tend to be bulky and heavy, which limits the ability to reduce switchgear size without compromising insulation safety.

Epoxy resin bushings offer a significant space-saving advantage due to their high dielectric strength combined with a more compact design. Their lightweight nature also reduces mechanical stress on switchgear structures, enabling slimmer and lighter units that meet strict dimensional constraints.

This compactness is especially valuable in urban substations, renewable energy installations, and indoor switchgear rooms where space is limited and efficient layout is critical.

Epoxy resin bushings are versatile and compatible with various switchgear insulation technologies, including SF6 gas-insulated switchgear (GIS) and air-insulated switchgear (AIS).

In SF6 GIS, the sealed environment requires insulation materials that do not contaminate the gas or degrade over time. The chemical stability and inert nature of epoxy resin ensure that bushings do not react with SF6 gas, maintaining the integrity of the gas insulation system.

In AIS, where switchgear components are exposed to ambient air and environmental conditions, epoxy resin bushings provide reliable insulation and mechanical support, benefiting from their resistance to moisture, pollution, and temperature fluctuations.

The evolving demands of modern electrical power systems require switchgear components that deliver superior insulation performance, mechanical strength, environmental resilience, and compact design. Epoxy resin bushings meet and exceed these requirements, making them the optimal choice for today’s switchgear applications.

Their excellent dielectric properties, resistance to tracking and partial discharge, along with thermal and moisture durability, contribute significantly to system reliability and safety. Furthermore, their lightweight and compact design support innovative, space-saving switchgear configurations.

For companies seeking reliable, high-quality epoxy resin bushings, Nanjing Rainbow Electric Co., Ltd. offers advanced solutions tailored to diverse industrial needs. With extensive experience and cutting-edge manufacturing capabilities, Nanjing Rainbow Electric stands as a trusted partner in delivering insulation excellence for switchgear systems worldwide.