- All

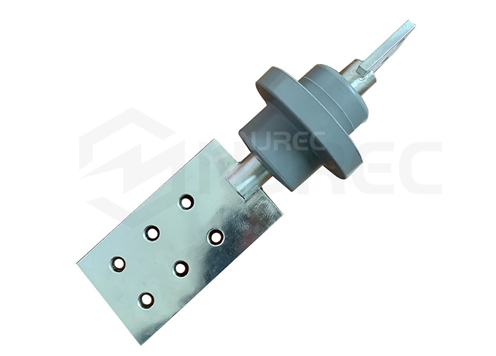

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Email: sales@njrecgroup.com

Views: 0 Author: Site Editor Publish Time: 2025-06-13 Origin: Site

Transformers are indispensable components of electrical power systems, enabling efficient transmission and distribution of electricity over long distances. While many are familiar with the general function of transformers—to step voltage levels up or down—some may overlook the critical role played by transformer bushings. These components might seem minor, but they are essential for ensuring the transformer operates safely and reliably.

At its core, a transformer bushing provides a safe, insulated pathway for electrical conductors to pass from the transformer's internal windings to the external circuitry. Without bushings, the electrical connections would be vulnerable to short circuits, electrical breakdowns, and mechanical damage.

A transformer bushing is an insulating device designed to allow an electrical conductor to safely pass through a grounded barrier such as the transformer tank or enclosure. The bushing provides both electrical insulation and mechanical support to prevent unintended contact between the conductor and the grounded transformer body.

Inside a transformer, high-voltage and low-voltage windings generate the necessary voltage transformation. These windings must connect to external power lines or circuits. The bushings serve as the conduit for these connections, maintaining the electrical isolation between the energized conductor and the grounded metal enclosure.

Transformers operate under high voltages, often ranging from a few kilovolts (kV) to hundreds of kV. The bushing must withstand this voltage difference without electrical breakdown. Therefore, they are constructed with high-quality insulating materials such as porcelain or epoxy resin, which provide dielectric strength—the ability to resist electrical stress.

Additionally, bushings provide mechanical strength, supporting the conductor and ensuring it remains securely positioned despite vibrations, thermal expansion, or external forces such as wind or seismic events. The integrity of this mechanical support is crucial for long-term transformer reliability.

Transformer bushings come in various designs and materials tailored to specific applications. Understanding the differences is vital when selecting the right bushing for your transformer system.

Epoxy resin bushings are relatively modern innovations that use solid cast epoxy to insulate the conductor. The epoxy material is molded around the conductor and includes internal grading layers to evenly distribute electrical stress.

Advantages:

Compact and lightweight design, ideal for space-constrained installations.

Excellent mechanical strength and impact resistance.

Superior moisture resistance due to sealed construction.

Compatible with both dry-type and oil-immersed transformers.

Easier to manufacture with precise shapes for customized applications.

Porcelain bushings are traditional and widely used in power transformers. Made from fired ceramic materials, porcelain offers excellent electrical insulation and mechanical strength.

Advantages:

Proven long-term reliability in outdoor environments.

High resistance to UV exposure, weathering, and pollution.

Well understood performance characteristics over decades of use.

However, porcelain bushings are heavy and brittle, making them more prone to damage from mechanical shocks and transportation.

Composite bushings combine materials, often using fiberglass-reinforced polymer and silicone rubber. These bushings offer a lightweight, hydrophobic, and weather-resistant alternative to porcelain.

Advantages:

Reduced weight simplifies installation.

Superior resistance to environmental contaminants.

Improved hydrophobicity helps resist pollution and moisture accumulation.

Composite bushings are increasingly popular in environments with high pollution or salt fog exposure, such as coastal substations.

Bushings are also categorized based on the type of transformer insulation system:

Oil-immersed bushings are designed to operate submerged in transformer oil. The oil acts as an additional insulation medium and coolant.

Dry-type bushings operate in transformers without oil, using solid insulation. These are common in indoor installations and environmentally sensitive locations.

Each type has specific design requirements to maintain dielectric strength and mechanical robustness under operational conditions.

To ensure reliable operation, bushings must meet stringent electrical and mechanical performance standards. The following are critical metrics used to evaluate bushings.

Dielectric strength is a measure of the maximum electric field the insulation can withstand without breakdown. High dielectric strength ensures that the bushing prevents flashovers or short circuits even under transient overvoltages like lightning surges.

Creepage distance is the shortest path along the surface of the insulating material between the energized conductor and grounded parts. A longer creepage distance improves resistance against surface tracking and contamination buildup, critical in polluted or wet environments.

Bushings must safely carry the transformer's rated current without excessive heating. The material and conductor design must allow efficient conduction while preventing thermal degradation of insulation.

Bushings must resist mechanical stresses from conductor weight, vibration, and external forces. This includes resistance to bending, compression, and torsional forces, ensuring the physical integrity of the insulation.

The bushing insulation must tolerate the operating temperature range of the transformer. Excessive heat can degrade insulation, leading to premature failure. Materials with high thermal stability and good heat dissipation properties extend service life.

Transformer bushings play a pivotal role in maintaining the overall safety and reliability of power distribution systems.

Poorly insulated or damaged bushings can cause internal short circuits, arc faults, or flashovers, which are dangerous and can cause transformer failures or outages. Reliable bushings reduce the likelihood of such incidents by maintaining solid insulation barriers.

Faulty bushings are a common cause of transformer outages and require costly repairs or replacements. Modern bushings designed with robust materials and protective features reduce maintenance needs and help utilities maintain continuous power supply.

Bushings exposed to outdoor conditions must resist rain, pollution, UV radiation, and temperature fluctuations. Durable bushings prevent moisture ingress and contamination, which can lead to insulation breakdown.

With the increasing integration of renewable energy and smart grid technologies, transformers are subjected to dynamic operating conditions. Advanced bushings with integrated monitoring sensors enable predictive maintenance, enhancing system resilience.

Transformer bushings are far more than simple components—they are vital to ensuring the safe, efficient, and reliable operation of transformers. Choosing the right type of bushing—whether porcelain, epoxy resin, or composite—based on specific application needs, environmental conditions, and performance criteria is crucial for optimizing transformer lifespan and minimizing operational risks.

Understanding the key functions, varieties, and performance standards of transformer bushings empowers power system designers and operators to maintain system stability and reduce downtime. For those interested in high-quality, cutting-edge bushing solutions tailored for modern transformer systems, Nanjing Rainbow Electric Co., Ltd. offers an extensive range of advanced insulation products. Their deep industry expertise and commitment to innovation make them a trusted partner in strengthening power infrastructure.

To learn more about their products and services or to discuss your specific needs, we highly recommend visiting www.njrecinsulator.com or contacting their professional team directly. Your transformer systems deserve the best in reliability and safety—Nanjing Rainbow Electric is here to help.